This building has had many lives, but originally it was a glass factory.

Jefferson Glass was a major producer of blown and pressed glass in Ontario.

This building has had many lives, but originally it was a glass factory.

Jefferson Glass was a major producer of blown and pressed glass in Ontario.

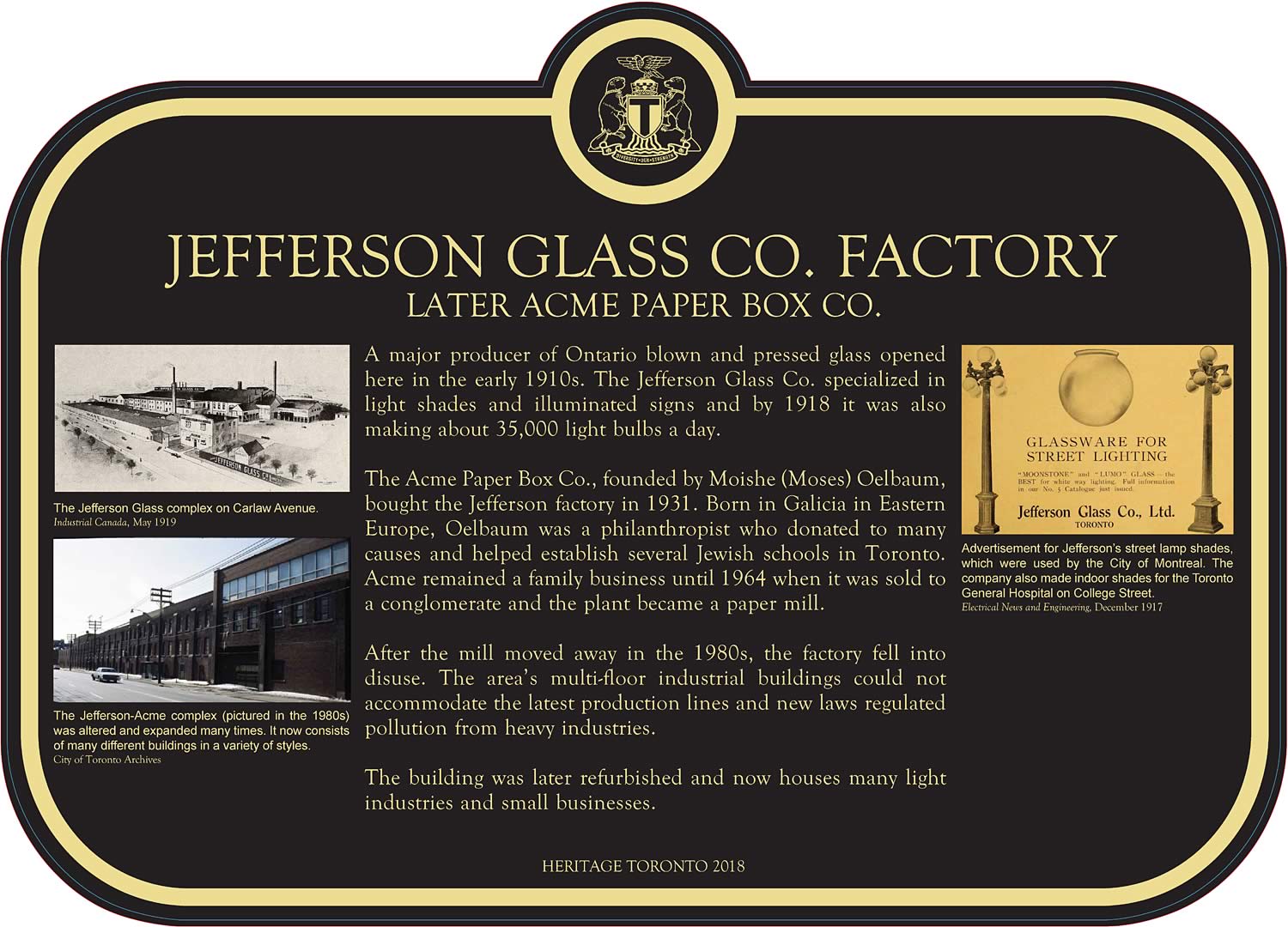

Jefferson Glass Co.

Location:

400 Carlaw Ave.

Year:

1912

Architect:

Various

Made:

Blown and pressed glass, light bulbs, light shades, and illuminated signs

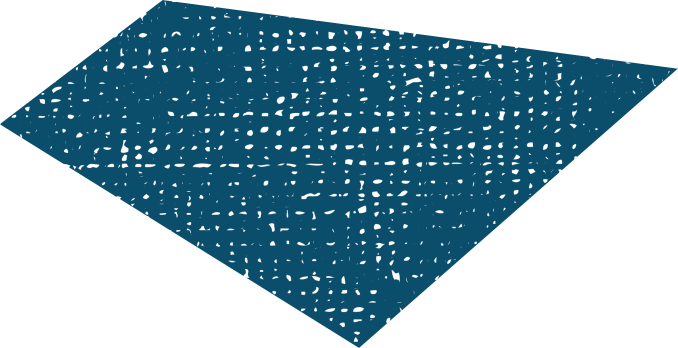

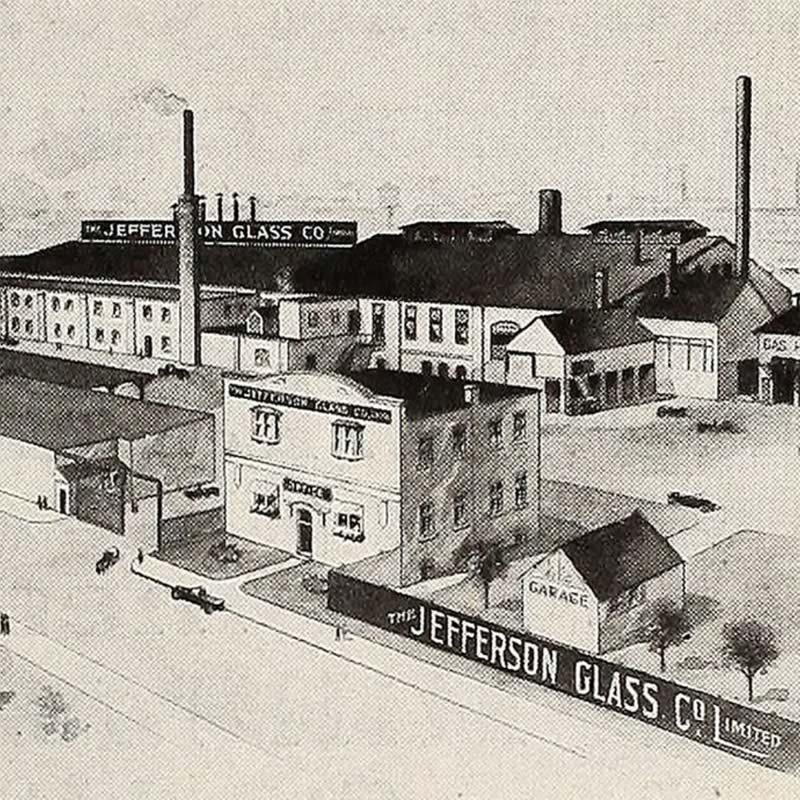

Left: The Jefferson Glass

Co. Ltd. plant, May 1919.

Industrial Canada

Right: Former Jefferson Glass Factory, later

Acme Paper Box, factory at 400 Carlaw Ave.

Image by Susan Drysdale

At its peak it made about 35,000 light bulbs a day on this site.

Business thrived when Jefferson made glass products for the military during the First World War. However, when peace returned, many unionized workers found themselves unemployed.

Living Memory

“I am a returned soldier …

I had just started work this morning

[at Jefferson] when the manager

came to me and said I would have to

quit as the union men objected

because I was not a member

[of their particular union].”

Private J. W. Tyson

speaking to the Toronto Star,

January 4, 1919

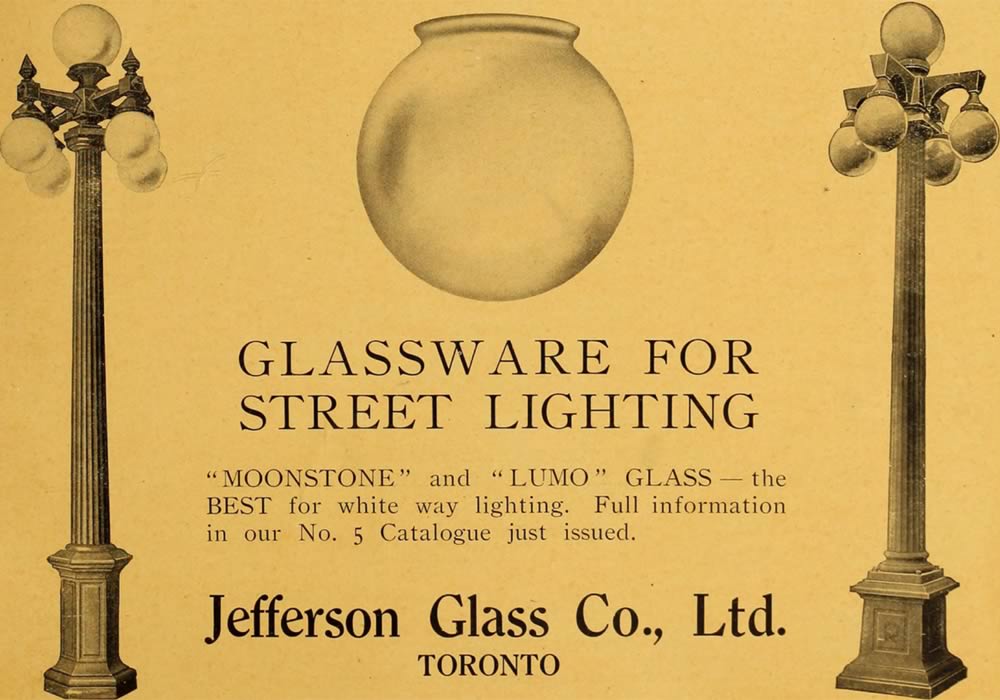

Advertisement for Jefferson Glass Co.

street lighting products, December 1917.

Electrical News and Engineering

Unions started to organize more efficiently.

One of the longest labour disruptions was in the fall and winter of 1954–55, when about 120 members of the United Electrical Workers union went on strike.

For five months, they fought for a wage increase and additional funding for health, welfare, and other benefits.

Globe and Mail, November 25, 1955

Globe and Mail, February 12, 1955

The strike was tense: the union reported strike-breaking action by public officials and police harassment of picketers.

In the Cold War political atmosphere, the union was also suspected of having communist sympathies.

Globe and Mail, April 1, 1955

The Acme Paper Box Company bought the Jefferson factory in 1931 and operated here for several decades.

Its owner was Jewish businessman and philanthropist Moishe (Moses) Oelbaum.

Acme wished the readers of

the Canadian Jewish News

happy High Holy Days in 1973.

Canadian Jewish News

Acme wished the readers of the Canadian

Jewish News happy High Holy Days in 1973.

Canadian Jewish News

The company added many new buildings to the Jefferson factory, resulting in the current architectural mishmash. Acme remained a family business until 1964 when it was sold to a conglomerate and the plant became a paper mill.

Fast Fact

“Acme”

For many, the name Acme will be forever associated with the Looney Tunes cartoon Wile E. Coyote and the Road Runner. At the time the cartoon was first produced, Acme was a common company name, literally meaning “the highest point.” The dubious quality of the products supplied by the cartoon Acme Corporation have, unfortunately, somewhat sullied the word.

Carlaw at Dundas looking north with the former

Jefferson/Acme factory in the background, circa 1980.

City of Toronto Archives

The 1960s brought disruption to the neighbourhood.

The design of the Carlaw factories could not support the latest production lines and new laws regulated pollution from heavy industries.

Companies began to relocate to the suburbs and there were many closures and layoffs. These triggered large protests calling for regulation of plant closures, which eventually became law.

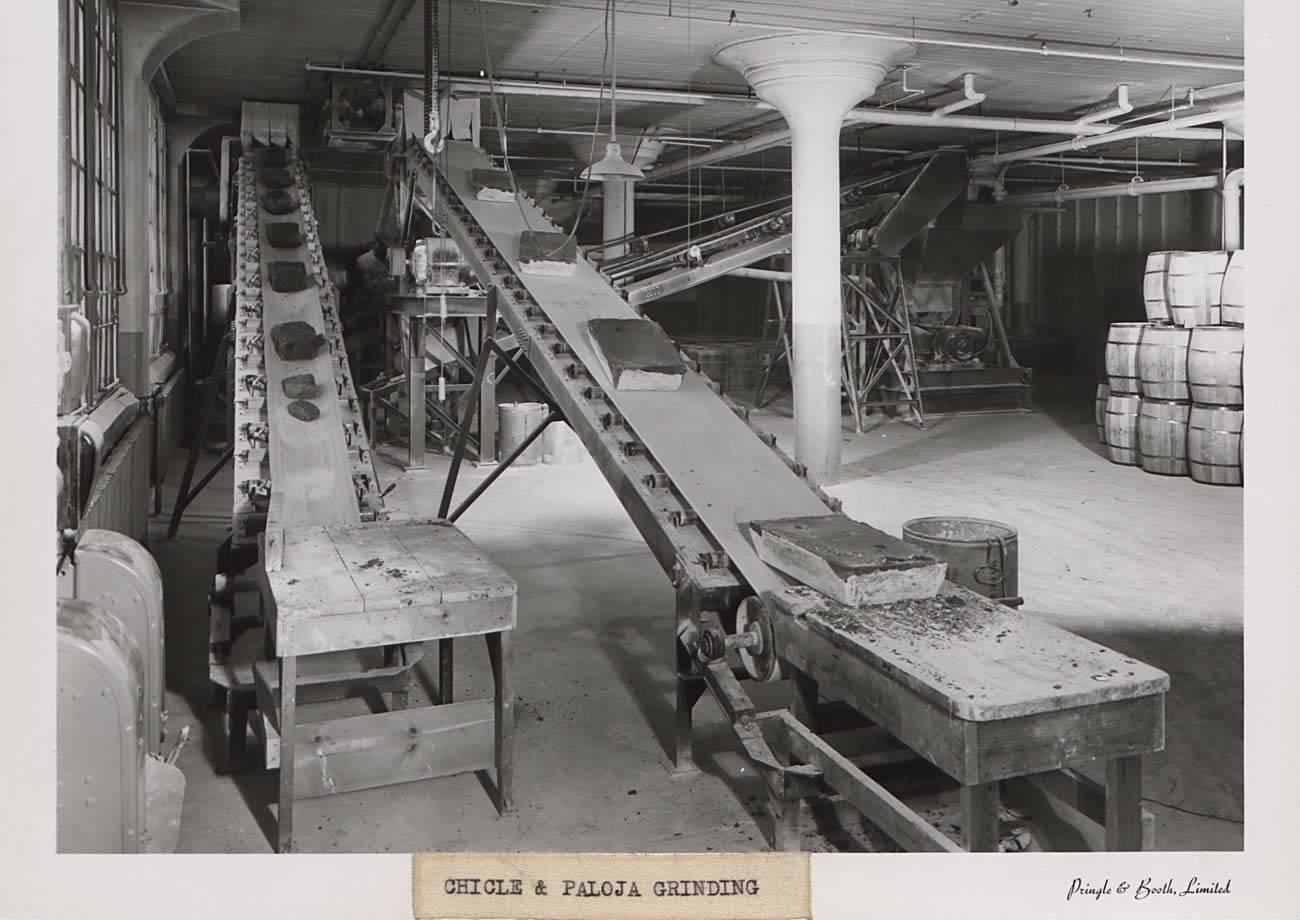

The typical multi-storey factory made extensive use of chutes and specialized rooms. New production lines were often open plan located within in a single large indoor space.

Sugar and Paloja grinding room,

Wrigley Factory, 1952.

Wrigley

Sugar and Paloja grinding room, Wrigley Factory, 1952.

Wrigley

Mixing department,

Wrigley Factory, 1952.

Wrigley

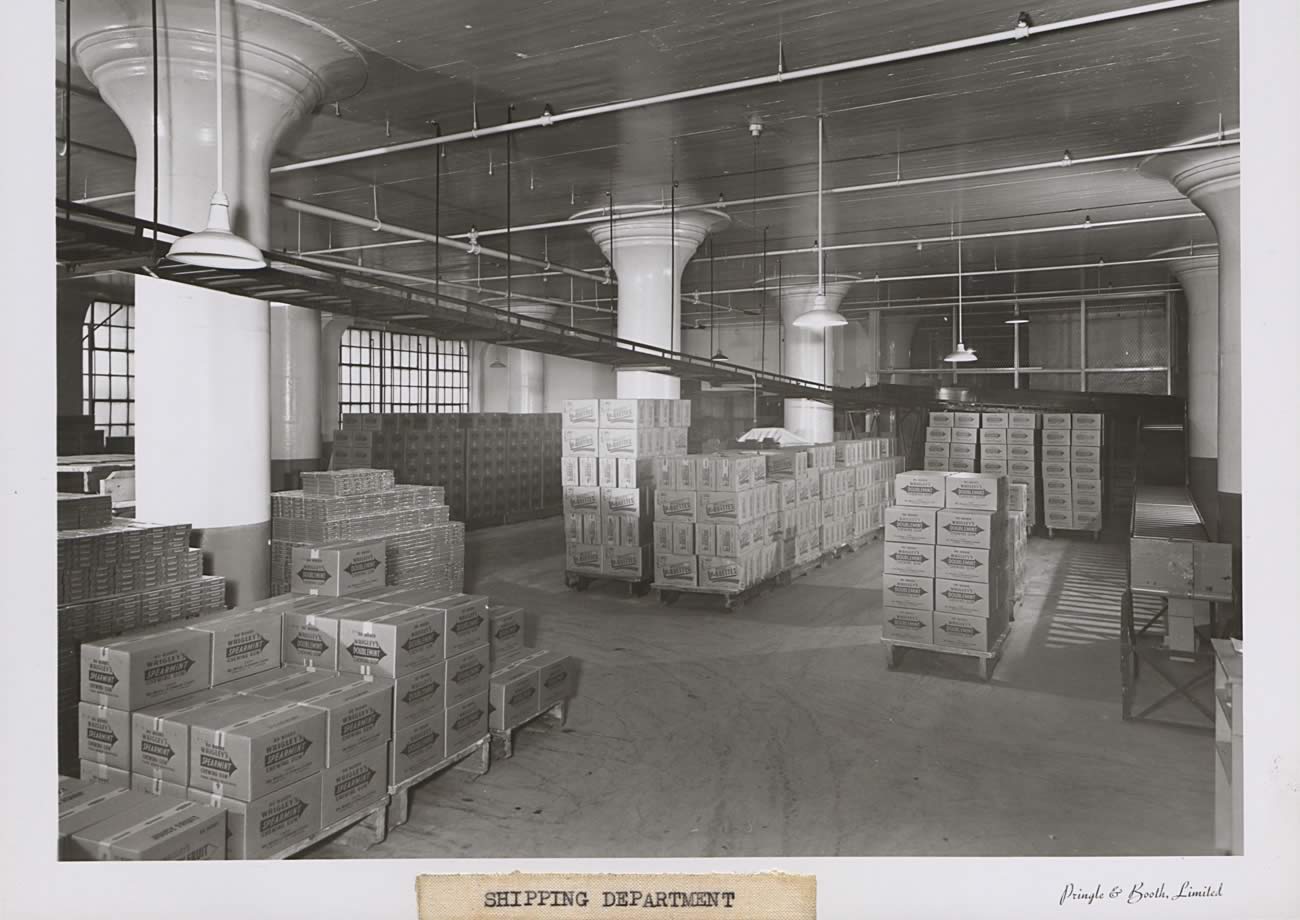

Shipping department,

Wrigley Factory, 1952.

Wrigley

Living Memory

“When the factories closed it left

an economic vacuum in the area.

But vacuums tend to get filled and

some far-reaching entrepreneurs

bought these buildings and cut

out spaces, then rented them.”

City planner Paul Winterton

speaking to the Toronto Star,

August 23, 1999

Check

it out ...

Read the plaque

JEFFERSON GLASS CO. FACTORY

LATER ACME PAPER BOX CO.

A major producer of Ontario blown and pressed glass opened here in the early 1910s. The Jefferson Glass Co. specialized in light shades and illuminated signs and by 1918 it was also making about 35, 000 light bulbs a day.

The Acme Paper Box Co., founded by Moishe (Moses) Oelbaum, bought the Jefferson factory in 1931. Born in Galicia in Eastern Europe, Oelbaum was a philanthropist who donated to many causes and helped establish several Jewish schools in Toronto. Acme remained a family business until 1964 when it was sold to a conglomerate and the plant became a paper mill.

After the mill moved away in the 1980s, the factory fell into disuse. The area’s multi-floor industrial buildings could not accommodate the latest production lines and new laws regulated pollution from heavy industries.

The building was later refurbished and now houses many light industries and small businesses.

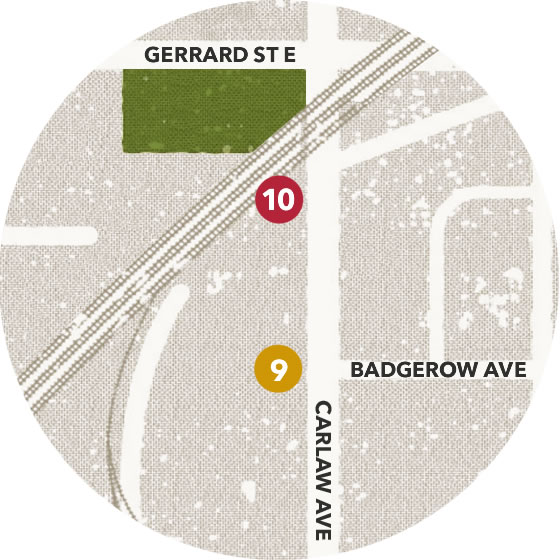

Ready to hit the next stop?

Continue north on Carlaw Ave. until just before the bridge. From here you can see the Toronto Hydro Building on the east side of Carlaw Ave. Stay on the west side of Carlaw Ave. for a better view.

Full steam

ahead!